Key words: granulator equipment, pot granulator, Zhengzhou mine granulator, granulator manufacturer

Page description: In August 2017, a Japanese company needed a pelletizing equipment for the production of fly ash, and ordered a pot pelletizer with a diameter of 2.4m from Henan Zhengzhou Mining Machinery Co., Ltd. On November 9, 2017, the granulator was manufactured as required and commissioned on-site, and was loaded and shipped on the 13th of that month.

Signing date: 2017-08-12

Processing material: fly ash

Processing capacity: 3t/h

Equipment configuration: pot granulator

1. Project Overview

Japanese researchers use fly ash to produce a compound fertilizer with high insoluble and slow effect. The main raw materials used are fly ash, crushed slag, phosphoric acid mixed liquid and other materials. The insoluble and slow-acting compound fertilizer prepared by using fly ash can inhibit the dissolution of potassium chloride in the presence of a large amount of water, increase the water absorption rate of the fertilizer, and reduce the fertilizer outflow. In 2017, a Japanese manufacturer ordered a pot granulator from Henan Zheng Mining Machinery Co., Ltd. due to the demand for granulating materials such as fly ash and crushed slag. On November 9, 2017, both parties carried out trial operation before shipment. 2017 The equipment was loaded and shipped on November 13, 2015.

2. Solution

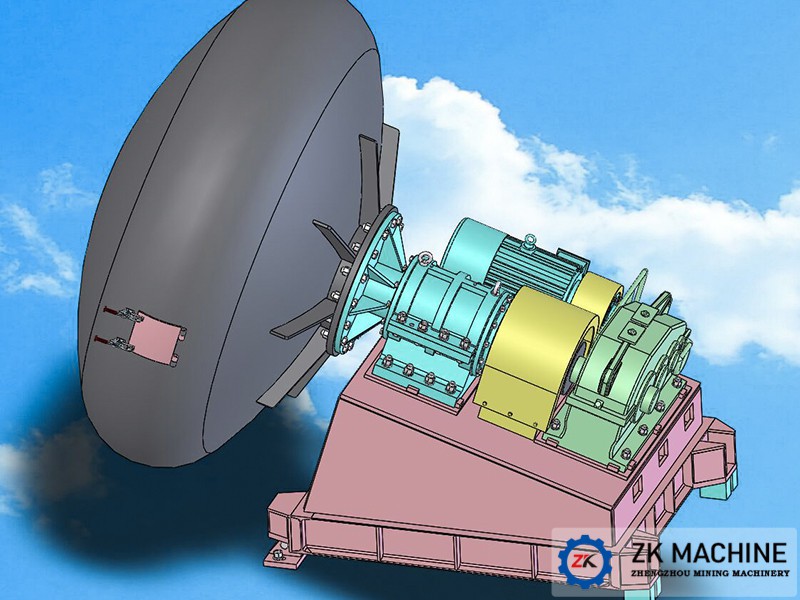

The granulator supplied this time is a pot granulator with a diameter of 2.4m, granulating 3 tons per hour, and mainly adopts the following solutions to meet customer needs:

1. According to the customer's granulation size range, recommend the equipment type for the customer, and combine the upstream and downstream production processes to reasonably arrange the process.

2. The frequency conversion speed motor is adopted, which is convenient for customers to adjust the speed according to the specific granulation requirements, and the operation is simple and convenient.

3. The base of the granulator adopts an integrated structure design, stable operation, low noise and long life.

3. Catalog picture