We can supply Clay Expanded Aggregate Production, Sludge Expanded Aggregate Production, Fly Ash & Sludge Expanded Aggregate Production by raw material, with different production process. We built our own expanded aggregate calcination experimental pilot platform, ceramsite proppant and expanded aggregated granulation platform and various experimental granulating equipment, which can realize various raw material analysis, calcination experiments, sample making, pilot production before industrial investment, so as to provide the basic industrial data for the later industrialization. For more detailed information, please feel free to contact with you directly.

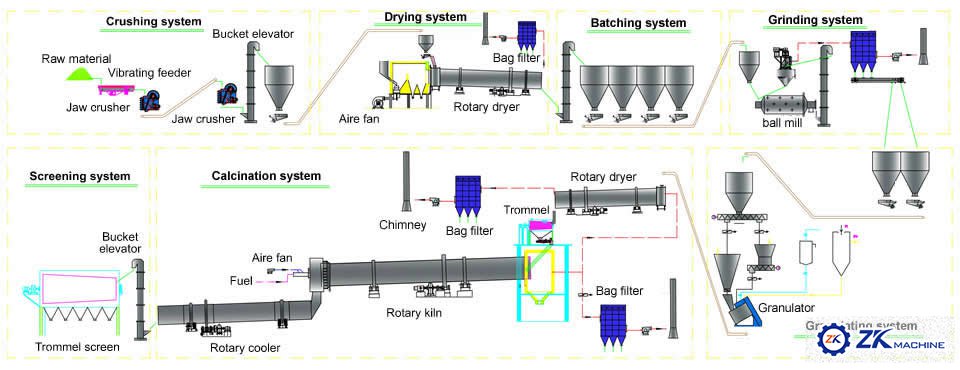

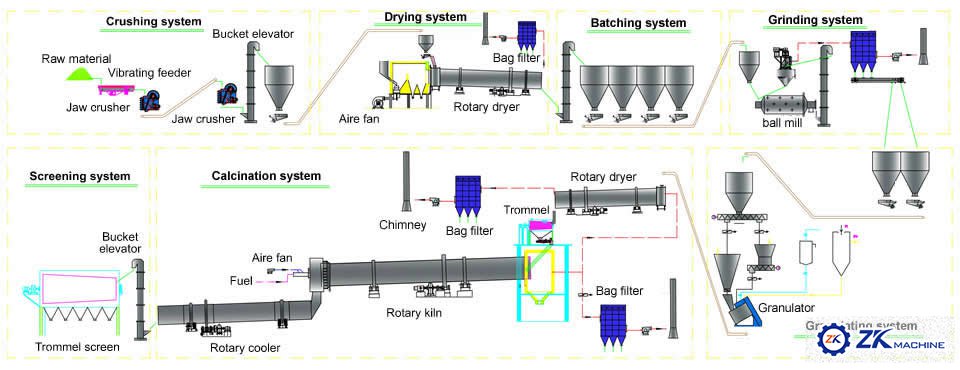

Basic Production Process:

When the raw material is clay or slurry, the production flow chart shall be consist of raw material process, mixing, granulating, insert type rotary kiln burning process, cooling process, screening and bag packing. When the raw material is shale, the production flow chart shall be consist of crushing, screening, single rotary kiln burning process, cooling process, screening and bag packing. The fuel could be coal, nature gas, biomass fuel and etc.