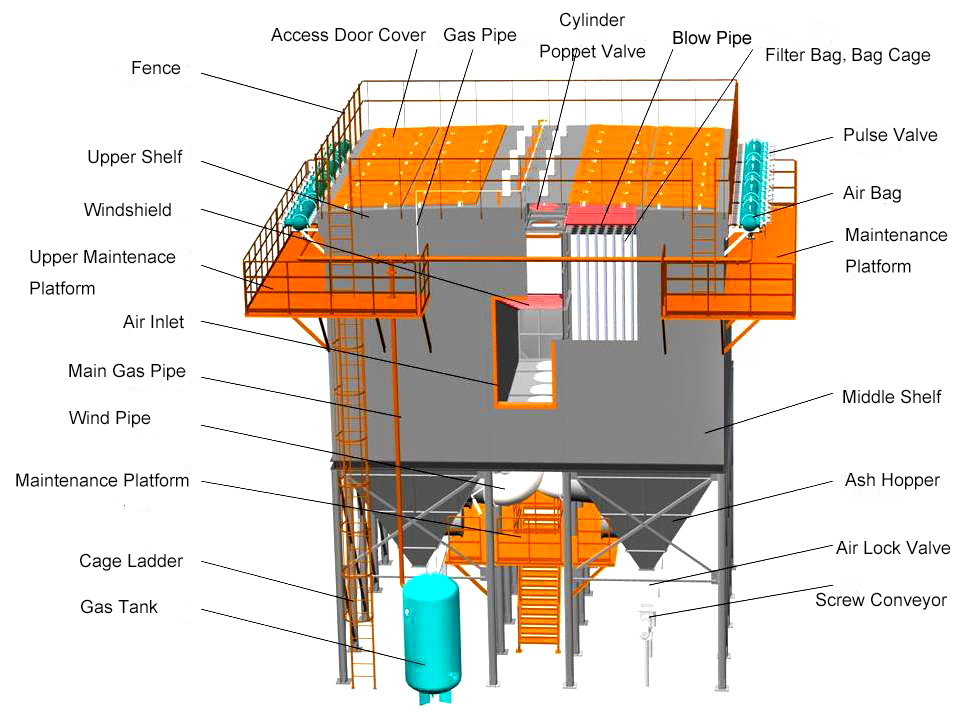

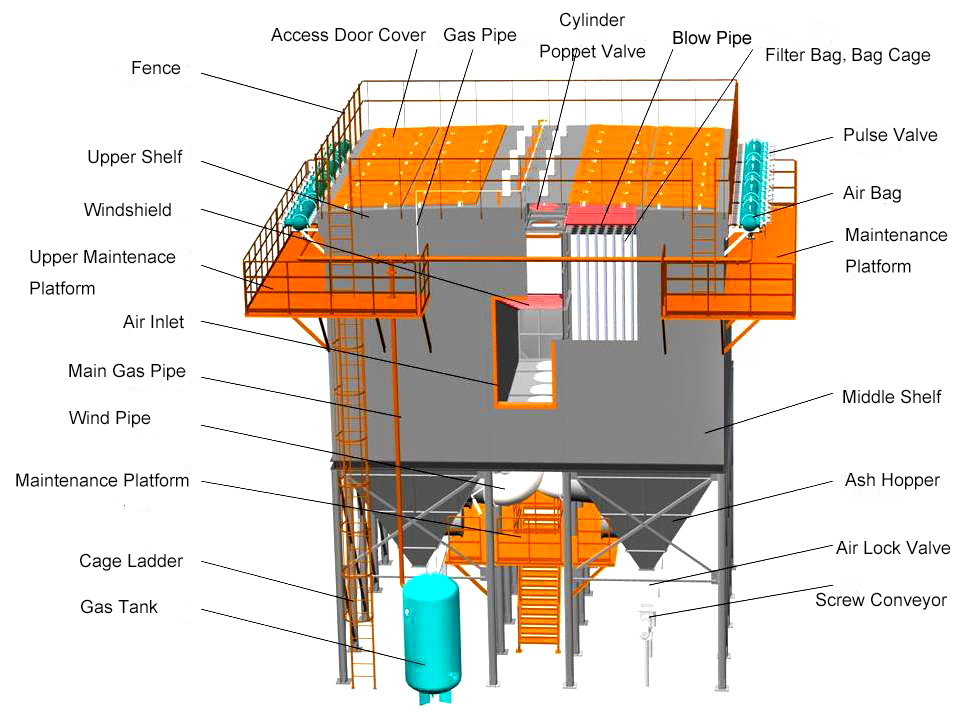

PPC Series Pulse Jet Bag Filter incorporates the advantages of other bag filters as compartmental blow-back, pulse jet cleaning. It is suitable to the treatment of high concentration dust, simplifying the technical process of dust treatment and reducing investment of device.

Application Scope

It's widely used in cement, building material, metallurgy, chemical and refractory industries, especially for the dust collection system, such as the crushing, packing, clinker cooling and various grinding mill in cement plant. It is also suitable for dust collection of coal grinding after some modification.

Advantages

1.New and advanced dust removing concept. No air pipe. Pulse valve is assembled at the side the chamber shell or top. No need to disassemble and assemble the air pipe when replacing the bags.

2.High performance pulse is applied to replace many smaller pulse to reduce the maintenance as much as possible. Multi-chamber and off-line dust removing. Long life of filter bag. Air tank will reduce the pressure decrease caused by equipment.

3.Available for high density dust containing air collection, for example, O-Sepa separator, the dust content of which will reach 1000g/Nm3.

4.It overcomes disadvantages of weak cleaning strength of blow-back as well as synchronous working of pulse jet cleaning and filtering, expanding the filed of application.

If you are interested in our product design, specification, spare parts, quotation etc, please feel free to contact us by WhatsApp +8617398960706, or email us at inczk@zkcorp.com.