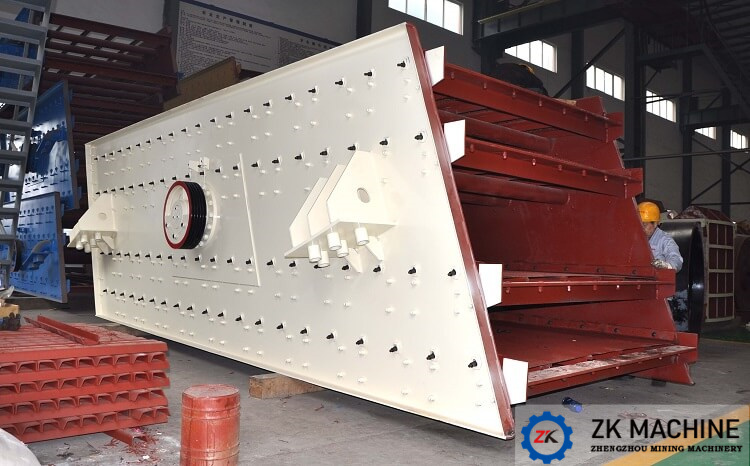

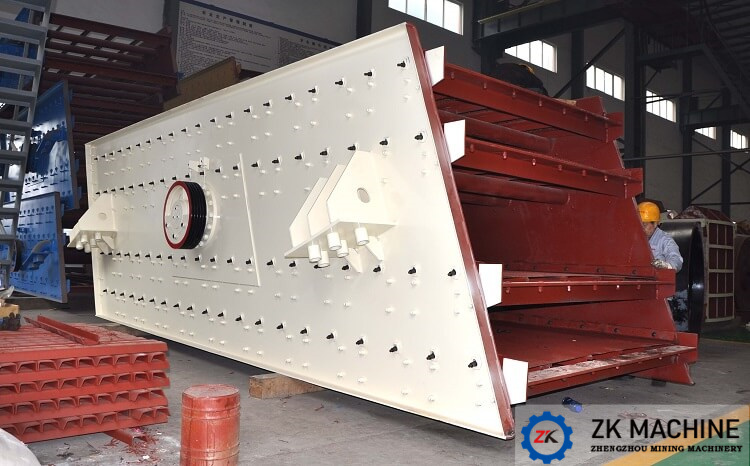

1. Product description

The multi-layer linear vibrating screen is mainly a seat-mounted multi-layer vibrating screening machine. It matches the corresponding screen plates according to the mesh number requirements of the materials screened by different products.It can screen and filter a variety of materials of different specifications at one time.and replace the screen mesh.Moreover, the screen replacement process is simple, the equipment is easy to operate, and the application range is wide.It is mainly used in the screening, classification, filtration and dehydration of granular and powdery materials in chemical industry, papermaking, metallurgical building materials, grain, abrasives, fertilizers and other industries.

2. Product Structure

Multi-layer linear vibrating screen mainly consists of screen box, screen plate, vibration motor and supporting device.

Box: Mainly made of Q235B steel plate welding, it can also be made of stainless steel plate welding according to application requirements.

Screen surface: The screen surface has two structural forms: stainless steel slit screen plate and metal wire braided mesh, which are fixed by vertical pressing and longitudinal tensioning respectively. The screen surface is easy and quick to replace and has a long service life.

Vibration motor: Two horizontal vibration motors are used to generate vibration sources, and the eccentric blocks at both ends of the motor are adjusted to adapt to different exciting force requirements.

Support device: The support device is composed of a support frame welded by channel steel and a support spring. By changing the height of the front and rear support legs, the inclination angle of the screen surface can be changed.

3. Operation and maintenance

1. Operators should be familiar with the performance, structural principles and maintenance checkpoints of each part of the equipment.

2. Equipment inspection should be carried out every shift to check whether the bolts in various parts are loose and whether the screen surface is loose or damaged. If the bolts are loose, tighten them in time. If the screen surface is damaged, replace it with a new surface in time.

3. The feeding amount should be as uniform and moderate as possible during operation. Except for special circumstances when the machine is shut down, it is strictly forbidden to shut down the machine with materials and continue to feed the screen machine after the machine is shut down.

4. The vibration motor is a key component of the equipment. The repair and maintenance of the motor should be carried out according to the vibration motor instruction manual.