1. Product Application

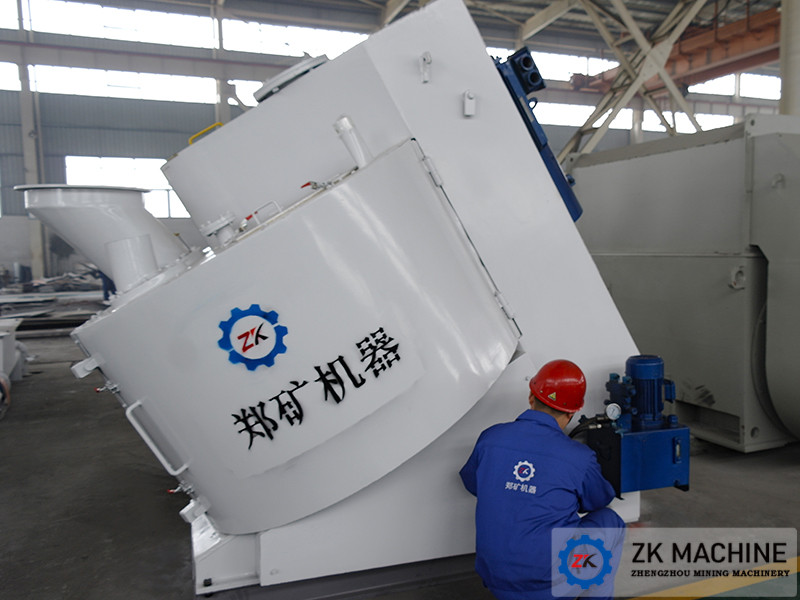

ZKH series clean powerful mixer is developed by our company on the basis of absorbing and learning from foreign advanced technology. It is mainly composed of machine base, frame, rotating drum, main transmission device, rotor, scraper assembly, discharge door, rotating drum power unit, sealing device and auxiliary system. Mainly used for mixing and mixing various solid, powder and liquid materials. It can be widely used in ceramsite, building materials, glass, metallurgy, ceramics, refractory materials, casting, batteries and environmental protection industries.

2. Working Principle

The rotating drum is installed at a characteristic angle and is equipped with a high-speed stirring rotor at its eccentric position. When the rotating drum rotates clockwise at a low speed, the material is continuously fed into the moving track of the high-speed counterclockwise rotating stirring blade. With the help of the rotation of the drum and the action of the scraper, a characteristic three-dimensional spatial flow field is formed that is conducive to mixing, so that the materials can be fully turned and mixed in a very short time, and the high efficiency and best uniform treatment effect can be realized.

3. Outstanding Advantages of ZKH Powerful Mixer

3.1. The whole process of mixing is carried out inside a fully enclosed drum, and the inside of the drum is in a state of slight negative pressure, no dust pollution, clean and environmentally friendly;

3.2. The inclined structure design adopts an optimized inclined angle to make the mixture produce a specific flow field inclined up and down. There will be no "back mixing" phenomenon in the drum, and a very high uniformity and good dispersion can be obtained. mixture;

3.3. Inclined structure design, even if only half or one third of the material is filled in the drum, a satisfactory mixing effect can be achieved;

3.4. The drum adopts a low-speed design, and the inner wall has a wear-resistant liner, so the equipment is less worn and has a long life;

3.5. The rotor mixing blades are treated with special surface to have high wear resistance. At the same time, the rotor blades should be designed with rapid replacement structure;

3.6. Multi-function scraper, to prevent the side wall and bottom plate of the drum from sticking to the phenomenon and speed up the unloading at the end of the mixing cycle. At the same time, replaceable parts are used in the structural design of the wearable parts to reduce maintenance costs;

3.7. High production efficiency, batch time period, production capacity can reach 24 batches/hour;

3.8. Using PLC control system, visualized operation, the mixing process can be directly modified through the operation panel, and the operation is simple;

3.9. Provide a variety of material interfaces, adjust rotation parameters and corresponding functional modules, which can meet the needs of different application industries and processes.

The above is the introduction about the application of the ZKH series clean powerful mixer. If you want to know more equipment information, please contact the customer service staff of Henan ZK Corp. Henan ZK Corp is a professional mining machinery and equipment manufacturer with rich technology accumulation and project experience. We sincerely invite you to visit our factory!