1.Introduction

Pot granulator is granulation equipment for bauxite, shale, clay, sludge, fly ash, slag, etc, which can produce particle size 5-25mm clay ceramsite, shale ceramsite, high strength ceramsite, refractory ceramsite, etc. It can be widely used in construction, fire insulation, oil fracturing proppant and other fields.

2. Component Structure & Features

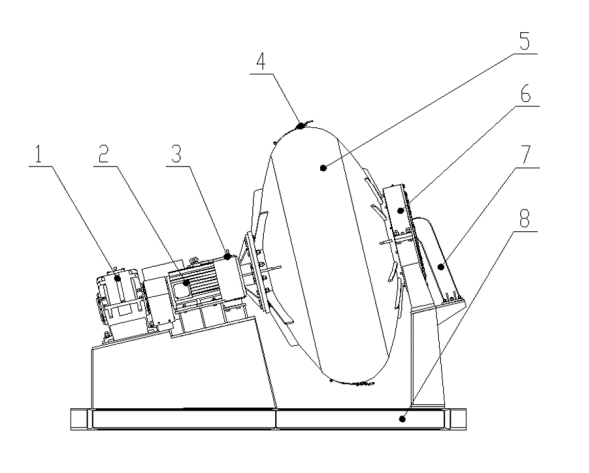

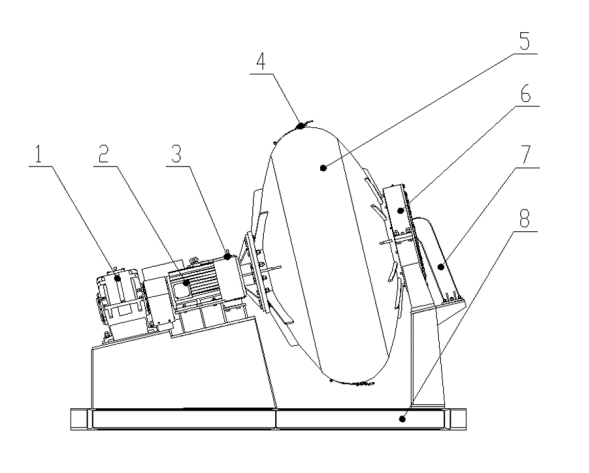

1-Reducer, 2-VVVF Motor, 3-Couplings Device, 4-Discharge Door,

5-Pot Granulator, 6-Rotary Supporting Device, 7-Scraper, 8-Rack.

3. Working Principle

Frequency conversion motor drives the reducer, drives the granulation pot to rotate through the bridge device, and the granulation pot axis and the horizontal surface is a specific Angle; Material in the granulation machine rolling at the same time to the pot water spray, small water droplets constantly sprayed on the material, material particles encounter water droplets quickly adsorption infiltration, particle surface to form a layer of very thin water film, and in the rolling adsorption of materials; Due to continuous water, feeding and rolling in the disc, the water film on the surface of the cue ball is also constantly absorbing and absorbing water, so that the cue ball gradually forms a feed ball; At the same time, due to the mechanical action of rolling, the compactness of the material ball is gradually increased, so that the material ball produces a certain mechanical strength, until the formation of the raw material ball meets the requirements, discharged through the discharge door.

4. Features

(1) Fully enclosed operation, to solve dust pollution, improve the working environment and material loss, with strong raw material adaptability, high production efficiency, product quality stability and other characteristics;

(2) The use of frequency conversion speed control, reduce the impact of equipment, stable operation, protect the motor, and reduce energy consumption by more than 30%;

(3) High pelleting rate, easy to control the size of the pellet, uniform particle size, good strength, overall pelleting, production efficiency greatly improved;

(4) the matching surface of the frame is processed by a large boring and milling machine to ensure the assembly accuracy of the equipment and improve the operation stability of the machine.

(Manufacturing)

(Shipment)