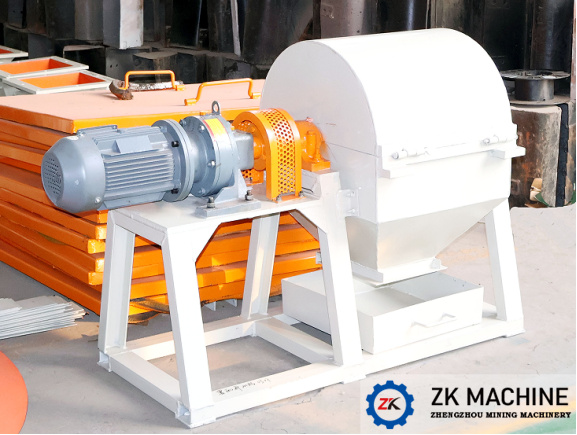

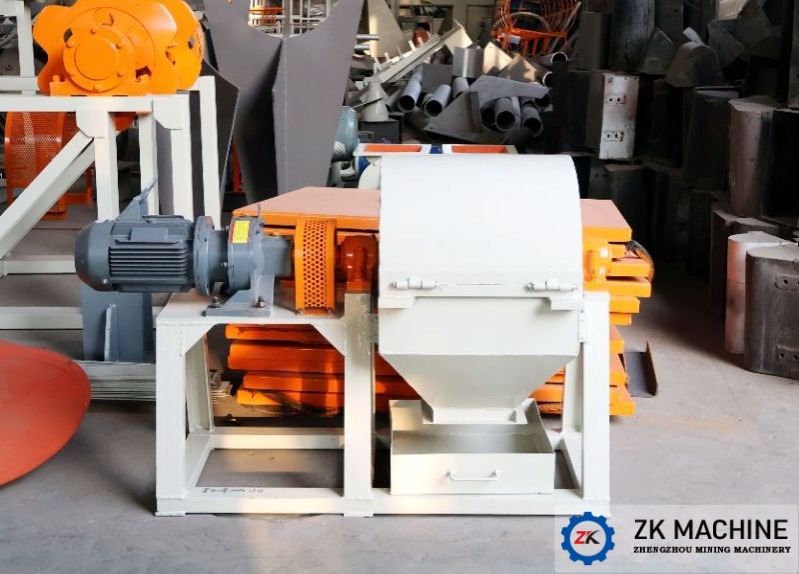

Laboratory ball mill (small-scale ball mill) is the key equipment for grinding materials after crushing. Based on different ore discharge methods, it can be divided into grid type and overflow type.

Our lab ball mills are available in sizes ranging from Φ0.9×1.12 to Φ1.8×2.1, with a loading capacity of 0.2–1.5 tons per batch, meeting various experimental needs. Suitable for grinding tests of ores, chemicals, ceramic raw materials, and more, their processing capacity ranges from a few kilograms up to 1000 kg. These mills support both wet and dry grinding and can handle brittle or fibrous materials, offering flexibility, reliability, and a compact design—ideal for laboratory and research applications. The output particle size can be adjusted down to 0.074mm to meet different requirements.

In addition to standard steel ball grinding media, we also provide laboratory rod mills equipped with long cylindrical steel rods, delivering customized solutions for specific experimental needs and application scenarios.

✔ Materials

Limestone, Cement, Clinker, Coal, Phosphate, Gypsum, Calcite, Calcium Carbonate, Magnesite, Kaolin, Clay, Feldspar, Talc, Mica, Bentonite, Spodumene, Barite, Quartz, Quartz Sand, Bauxite, Alumina Ore, Fluorite, Granite, Marble, Manganese Ore, Slag, Steel Slag, Slag Powder, Aluminum Powder, Fly Ash, Coal Gangue, Coal Powder, White Ash, Glass etc.

✔ Advantages

1. Adopt ultra-thick steel plate; strong cylinder structure design.

2. High manganese steel lining plate with good wear resistant and long service life.

3. Mini ball mill base seat is made of high quality Babbitt metal ensuring the stable operation of the whole machine.

4. Pinion gear and bull gears with high strength and high precision, high quality reduction gear and motor. Professional design and manufacturing process, on time delivery, fast shipping.

5. The Mill Ball Mills work stably and reliably, and can be divided into dry Ball Mills and wet Ball Mills according to the materials to be grinded and the discharging styles.